Resin flooring – Application Areas

Food & beverage

HACCP-certified resin flooring. Total hygiene. Zero compromises.

Food safety. It starts from the floor.

Resin flooring, for the food & beverage industry involved in food processing (from raw material processing, packaging, and storage to the preparation of sales areas and/or sales/dining areas) ensures compliance with the most stringent HACCP health regulations to prevent food contamination and workplace safety. Continuous resin surfaces prevent the accumulation of bacteria, fungi, mold, and dirt caused by production processes and frequent washing. We offer resin solutions specifically designed to meet the multiple and specific needs of each branch of the food industry, certified, sustainable, high-performance, and durable.

Nonslip

HACCP Certificate

Crack bridging

Chemical resistant

Fire resistance class Bfl-s1

Work Safely

VOC Free

Contributes to LEED credits

Application areas

High-performance resin solutions for mills and the milling industry: Our HACCP-compliant, waterproof and dustproof flooring is easily sanitised and designed to withstand heavy loads, abrasion from dust, flour and semolina, machinery vibrations, and continuous contact with flour and cereals.

Seamless resin surfaces that prevent the build-up of organic residue and can withstand temperature changes, constant humidity and intensive sanitation cycles. HACCP-compliant, waterproof coatings are designed to withstand prolonged contact with lactic acids, whey and animal fats. Our certified non-slip surfaces guarantee maximum safety for operators, even in the presence of liquids and condensation. They are ideal for use in milk plants, dairies, and production facilities for cheese, yoghurt, and butter.

Monolithic resin surfaces that are resistant to blood, animal fats, oils, proteins, and intensive, high-pressure washing with aggressive detergents. The waterproof, non-slip coatings are designed to withstand temperature changes between cold rooms and processing areas, as well as heavy traffic from trolleys and machinery. They ensure maximum hygiene in slaughterhouses, sausage factories, and processing plants for fresh and processed meat and fish, and comply with HACCP standards.

This HACCP-compliant, continuous resin flooring prevents oil and grease infiltration. It is also chemically resistant to extraction solvents and alkaline detergents, and guarantees maximum slip resistance, even when oily residues are present. The waterproof, easily sanitised, food-grade compliant coatings are designed for use in olive pressing, vegetable oil extraction, storage and packaging environments.

High-performance resin surfaces for industrial bakeries and patisseries: continuous flooring that prevents the build-up of flour and microscopic dust, and resists caramelised sugars, fats, high temperatures near ovens, and humidity in proofing areas. Our certified, waterproof, HACCP-compliant, anti-slip coatings are designed for environments with heavy footfall, repeated thermal cycles and frequent cleaning. These surfaces are ideal for bread production, as well as for use in biscuit and confectionery factories.

Continuous flooring prevents the accumulation of cocoa dust and fatty residues. It is resistant to controlled temperatures in tempering areas and to melted cocoa butter and sugars. The HACCP-certified, waterproof, non-slip coatings are designed for environments with controlled humidity, precise thermal cycles and frequent cleaning. These coatings are ideal for use in cocoa processing plants, chocolate production facilities and industrial praline manufacturing plants.

High-performance resin surfaces for industrial pasta factories: continuous flooring that prevents the accumulation of flour and micro-dust, and can withstand high humidity in fresh pasta production areas and the controlled temperatures and pasteurisation steam in dryers. Our certified, waterproof, HACCP-compliant, anti-slip coatings are designed for environments with repeated thermal cycles, heavy traffic and frequent cleaning. These surfaces are ideal for dry pasta, fresh pasta, filled pasta and extrusion plants.

In factories producing vegetable preserves, ready-made sauces, purées, peeled tomatoes and tomato concentrates, continuous and durable resin flooring is required. This flooring must be highly resistant to tomato stains and infiltration, organic acids and vegetable pigments. It must also be able to withstand the high temperatures of pasteurisation, steam and sterilisation cycles. Anti-slip coatings are certified, waterproof and HACCP-compliant, and are designed for environments with frequent high-pressure washing and heavy traffic of trolleys and pallets.

The ready-made food, food packaging and frozen food industries, including temperature-controlled warehouses, present a unique set of challenges for flooring. As well as having to comply with strict health and hygiene regulations, these floors must be able to withstand extreme temperatures (both cold and hot), heavy footfall, spills of organic substances, and the corrosive effects of cleaning and sanitising chemicals. Inappropriate flooring can compromise food safety, increase maintenance costs and slow down production. Our resin solutions are certified for food contact. They are resistant to extreme temperatures down to -30°C and below. They are also waterproof and easy to sanitise. They are resistant to chemicals and heavy traffic. They are safe and non-slip, even at low temperatures. They are ideal for processing rooms, cold rooms, packaging areas, warehouses, loading/unloading areas and quality control laboratories. They ensure food safety, durability and regulatory compliance.

The high temperatures of roasting ovens, the abrasiveness of coffee beans, oil spills, and the need for frequent cleaning all pose significant challenges. Therefore, choosing the right flooring is crucial to ensuring an efficient and safe working environment that complies with food regulations. Resin flooring solutions are designed to withstand the thermal, mechanical and chemical stresses typical of such environments while maintaining high hygiene and safety standards.

The beverage industry, including the production of soft drinks, juices, and mineral waters, requires flooring that meets the highest hygiene, safety, and resistance standards, even in warehouse areas. Production, bottling, and storage environments are subject to continuous mechanical, chemical, and thermal stress. For this reason, we offer resin coatings that are specifically designed to withstand spills of acidic or sugary liquids, heavy forklift traffic, temperature changes, and rigorous cleaning procedures.

CHANNELS, COLLECTION WELLS AND WALL FITTINGS

To prevent the accumulation of dirt, bacteria, and potentially contaminating processing residues, the design and installation of drains for the collection and removal of liquids is important. In accordance with HACCP standards, a surface equipped with a drainage system helps to increase the level of hygiene and operator safety. Fillets more effectively prevent dirt and bacteria from settling in the cracks between perimeter walls and the floor, making the flooring continuous and surfaces easier to clean.

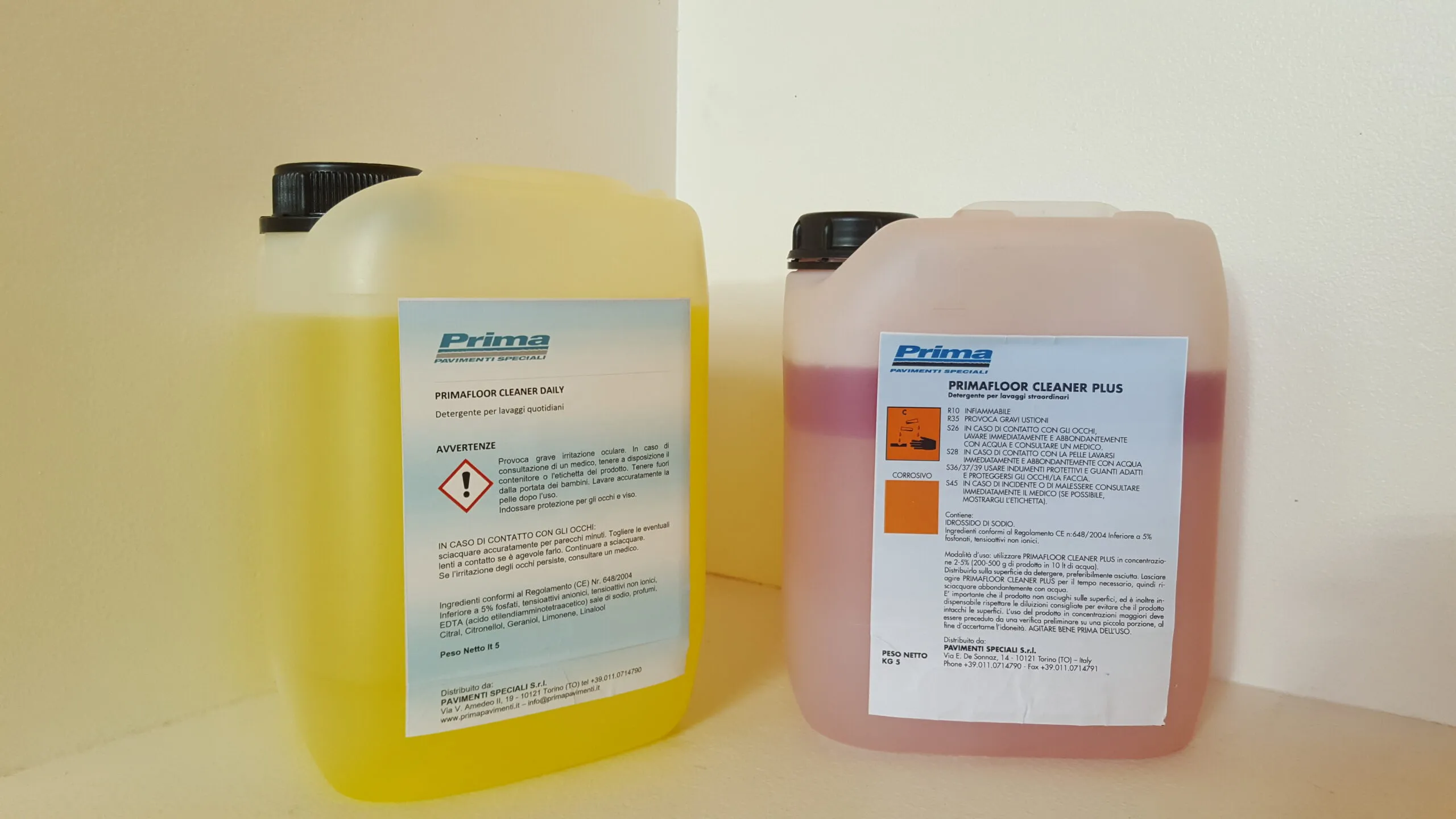

PROFESSIONAL DETERGENTS PRIMAFLOOR

PrimaFloor Cleaner professional cleaners line for resin floors.

Where

- Fruit and vegetables

- Dairy

- Meat and fish processing

- Confectionery & bakery, roasting

- Canning industry

- Pasta production

- Oil mills, wineries, breweries

- Food packaging, ready meals

- Warehouses, cold storage

- Bottling

- Kitchens and canteens, food areas, sales areas

Food environments

- Goods receiving

- Raw materials warehouse

- Production and processing

- Packaging

- Finished goods warehouse

- Dispatch area

- Technical rooms

- Trolley charging area

- Employee changing rooms

- Offices

- Outdoor areas