Resin Flooring

Polyurethane cement coatings

Sika® Ucrete® The world’s most durable industrial flooring

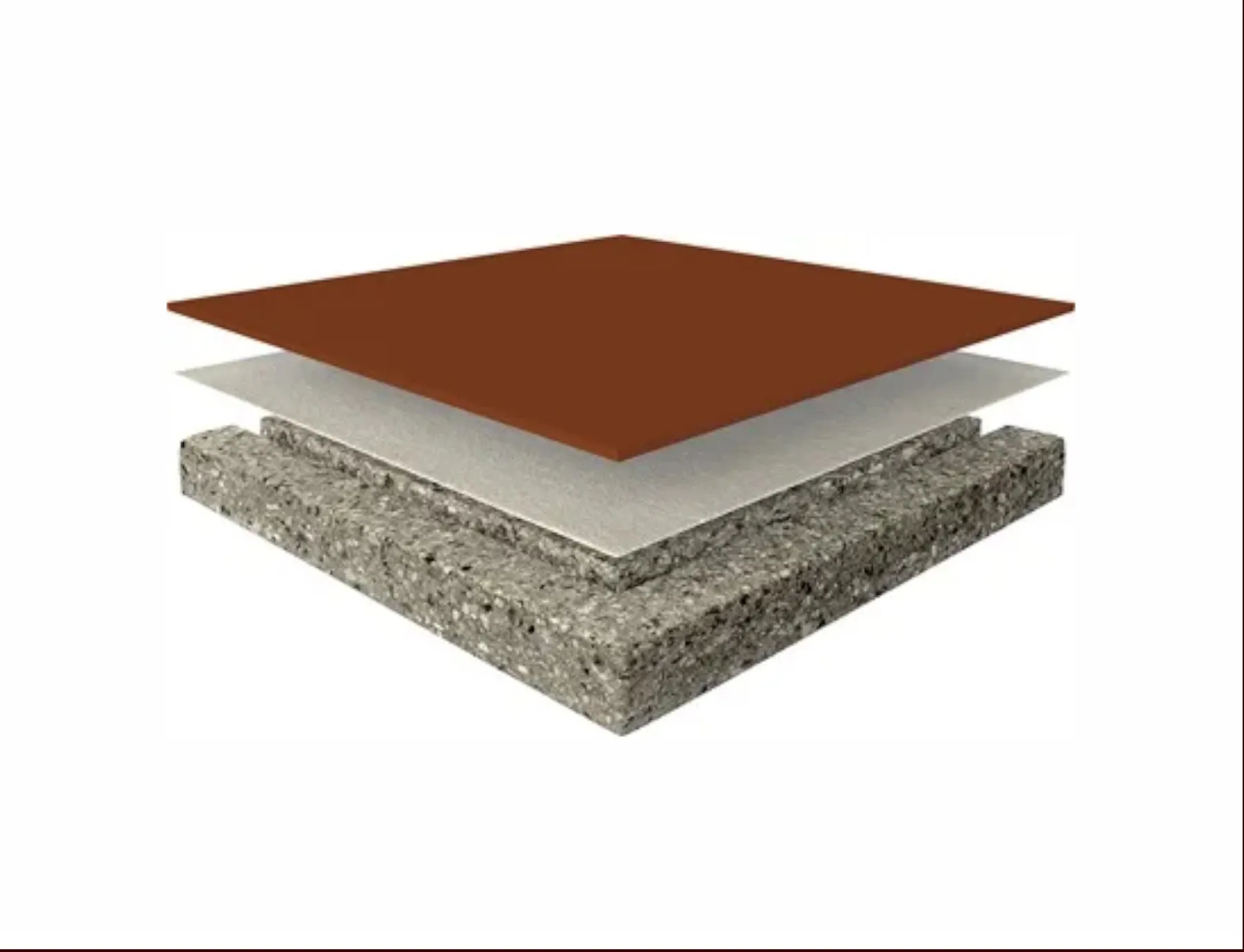

Self-levelling polyurethane-cement flooring, thickness 4-6 mm

This polyurethane-cement system is used as a preparatory screed for Sika® Ucrete® floors in dry process areas.

Designed to withstand high levels of stress, this solution is notable for its resistance to bacterial and fungal growth, ensuring hygienically safe environments in accordance with HACCP standards. It can be applied to concrete after just 7 days and to polymer screeds after only 3 days, which significantly reduces construction time.

The system offers high resistance to aggressive chemicals, heavy abrasion, thermal shock and impact, as well as high mechanical strength and total impermeability to liquids. As a low VOC emission system, it complies with the most stringent environmental standards. Its thermal expansion properties are similar to those of concrete, ensuring dimensional stability over time.

Technical solution

Ucrete MF

ADVANTAGES

Suitable for application on 7-day-old concrete and 3-day-old polymer screeds

Suitable for application on 7-day-old concrete and 3-day-old polymer screeds Total waterproofing

Total waterproofing Does not contaminate from the mixing stage onwards

Does not contaminate from the mixing stage onwards Resistant to the growth of bacteria or mould

Resistant to the growth of bacteria or mouldintended use

- Food industry

- Food warehouses

- Chemical and treatment plants

- Clean rooms

- Dry packaging lines

- Storage areas

Antistatic and self-levelling polyurethane-cement flooring

This heavy-duty polyurethane-cement system provides a smooth, protective, antistatic finish that is suitable for predominantly dry ESD and ECF environments. It is electrostatic conductive and is used in dry process areas in the electronics industry to protect sensitive electronic devices, as well as in areas at risk of explosion.

The application can be carried out on concrete after just 7 days and on polymer screeds after only 3 days, which significantly reduces construction time.

The system provides excellent resistance to specific chemicals, high mechanical strength, and complete impermeability to liquids. As a low VOC emission system, it complies with the most stringent environmental standards. Its thermal expansion properties are similar to those of concrete, ensuring dimensional stability over time.

Technical solution

Ucrete MF40AS

ADVANTAGES

Suitable for application on 7-day-old concrete and 3-day-old polymer screeds

Suitable for application on 7-day-old concrete and 3-day-old polymer screeds Total waterproofing

Total waterproofing Excellent resistance to specific chemicals

Excellent resistance to specific chemicals High mechanical strength

High mechanical strengthintended use

- Food industry

- Pharmaceutical companies

- Chemical and treatment plants

- Clean rooms

- Electronic facilities and data centres

- Defence organisations

Polyurethane-cement flooring 6 mm thick

This is a polyurethane-cement system for high-stress applications. It is applied with a trowel to a thickness of 6 mm and has a slightly rough finish. It is ideal for situations where a quick return to service is required, whether in new or existing structures.

The application can be carried out on concrete after just 7 days and on polymer screeds after only 3 days, which significantly reduces construction time. The system provides excellent resistance to specific chemicals, high mechanical strength, and complete impermeability to liquids. As a low VOC emission system, it complies with the most stringent environmental standards. Its thermal expansion properties are similar to those of concrete, ensuring dimensional stability over time.

Technical solution

Ucrete HF60RT

ADVANTAGES

Suitable for application on 7-day-old concrete and 3-day-old polymer screeds

Suitable for application on 7-day-old concrete and 3-day-old polymer screeds Quick application

Quick application Total waterproofing

Total waterproofing High mechanical strength

High mechanical strengthintended use

- Food industry

- Pharmaceutical companies

- Chemical and treatment plants

- Production plants and workshops

Multi-layer anti-slip polyurethane-cement system

This is a heavy-duty polyurethane-cement flooring system with high slip resistance. It offers excellent resistance to aggressive chemicals, heavy impact and high temperatures.

Non-slip, wear-resistant, low viscosity, high solids content and solvent-free. It is used in wet and dry process areas. Suitable for indoor and outdoor use for the protection and waterproofing of car park floors and garage floors.

The application can be carried out on concrete after just 7 days and on polymer screeds after only 3 days, which significantly reduces construction time. The system provides excellent resistance to specific chemicals, high mechanical strength, and complete impermeability to liquids. As a low VOC emission system, it complies with the most stringent environmental standards. Its thermal expansion properties are similar to those of concrete, ensuring dimensional stability over time.

Technical solution

Ucrete DP10

ADVANTAGES

Resistance to high temperatures

Resistance to high temperatures Suitable for application on 7-day-old concrete and 3-day-old polymer screeds

Suitable for application on 7-day-old concrete and 3-day-old polymer screeds Excellent resistance to specific chemicals

Excellent resistance to specific chemicals Total waterproofing

Total waterproofingintended use

- Food industry

- Pharmaceutical companies

- Chemical and treatment plants